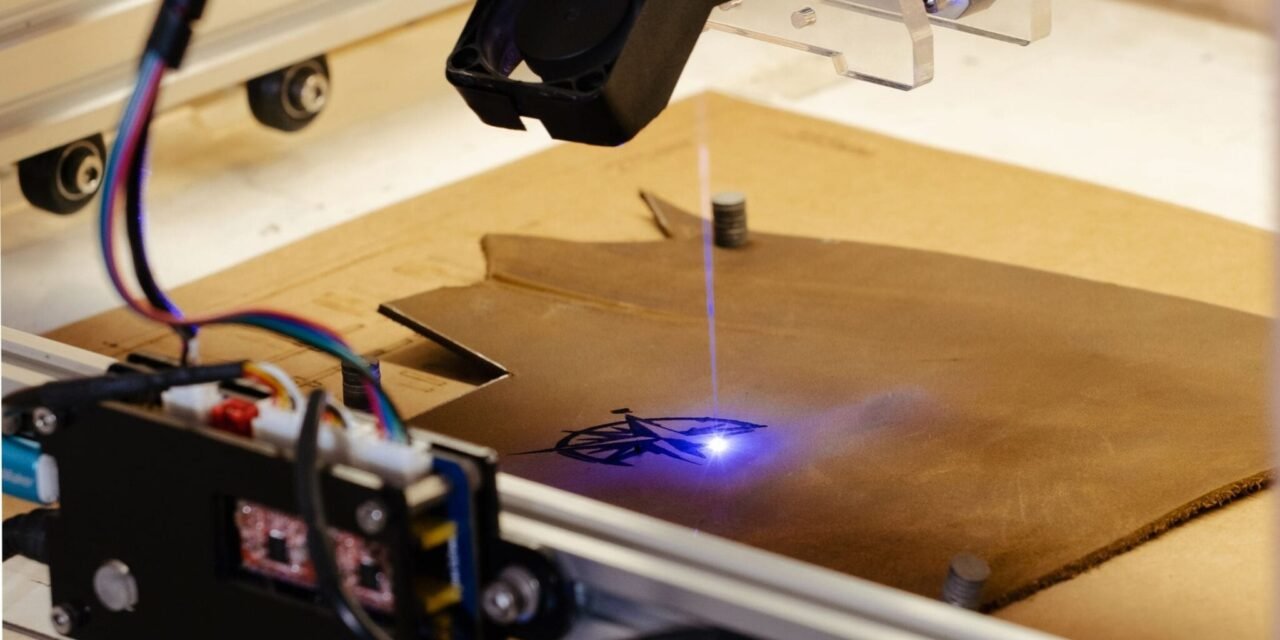

Laser cutting has significantly improved precision and efficiency in leather footwear production, offering a host of benefits over traditional cutting methods. Here’s how laser cutting enhances the process:

1. Superior Precision and Accuracy

- Fine Details: Laser cutting machines can create intricate patterns, perforations, and designs with exceptional precision, down to fractions of a millimeter.

- Consistency: Unlike manual cutting, which can vary in accuracy, laser cutting ensures uniformity across all pieces, crucial for mass production or symmetrical designs.

- Complex Patterns: Allows the creation of detailed and delicate patterns, such as broguing or custom engravings, without risk of error.

2. Cleaner and Sharper Edges

- No Fraying: The heat from the laser seals the edges of the leather during cutting, preventing fraying or splitting.

- Smooth Finishes: Produces smooth, clean edges that require little to no additional finishing, saving time and improving aesthetics.

3. Efficiency and Speed

- Faster Cutting: Laser cutting machines work significantly faster than manual or die-cutting methods, especially for complex designs or large batches.

- Simultaneous Cutting: Multiple layers of leather can be cut simultaneously, improving productivity without compromising quality.

4. Reduced Waste

- Material Optimization: The precise control of laser cutting reduces material wastage, as the software optimizes the layout of patterns to minimize offcuts.

- Cost Efficiency: Less wasted leather translates to cost savings in production.

5. Versatility

- Compatibility with Various Leathers: Laser cutting works on a wide range of leather types, including full-grain, suede, and even exotic leathers, without compromising quality.

- Adaptability: Can handle varying thicknesses and textures, allowing for greater flexibility in design and material selection.

6. Customization and Personalization

- Unique Designs: Enables the creation of custom patterns, monograms, and logos for bespoke or limited-edition footwear.

- Quick Adjustments: Designs can be adjusted digitally and implemented instantly, offering rapid prototyping and customization.

7. Reduction in Manual Labor

- Automation: Laser cutting automates the most time-consuming and labor-intensive aspects of leather cutting.

- Skill Requirements: Reduces dependence on highly skilled manual labor, as the precision is handled by the machine.

8. Improved Safety

- Minimized Risks: Eliminates the need for sharp cutting tools, reducing the risk of accidents for workers.

- Controlled Environment: Laser cutting is typically conducted in a controlled, enclosed environment, improving overall workplace safety.

9. Scalability

- From Prototyping to Production: Laser cutting is equally effective for small-scale prototypes and large-scale production runs, offering consistent quality at any scale.

Applications in Footwear Production

- Upper Cutting: Creating precisely shaped panels for shoe uppers.

- Perforations: Adding decorative or functional perforations for breathability.

- Insole and Sole Patterns: Cutting insoles and outsoles with precision, ensuring proper alignment and fit.

- Engraving: Adding logos, branding, or artistic details directly onto the leather.

Challenges and Considerations

- Burn Marks: If not properly calibrated, the laser can leave scorch marks on lighter-colored leathers.

- Cost of Equipment: High-quality laser cutting machines require significant upfront investment.

- Skill for Operation: While less manual, operators need training to handle the software and machine settings for optimal results.

Conclusion

Laser cutting enhances the precision, efficiency, and customization of leather footwear production. It reduces waste, improves quality, and opens up new design possibilities, making it an indispensable tool for modern shoemakers aiming for excellence and innovation.

Hashtags

#LaserCuttingInFootwear #PrecisionLeatherCrafting #LaserTechInShoes #FootwearManufacturingInnovation #LeatherShoeProduction #AdvancedShoeCrafting #LaserCutLeather #FootwearPrecisionDesign #InnovativeShoeMaking #TechInLeatherFootwear