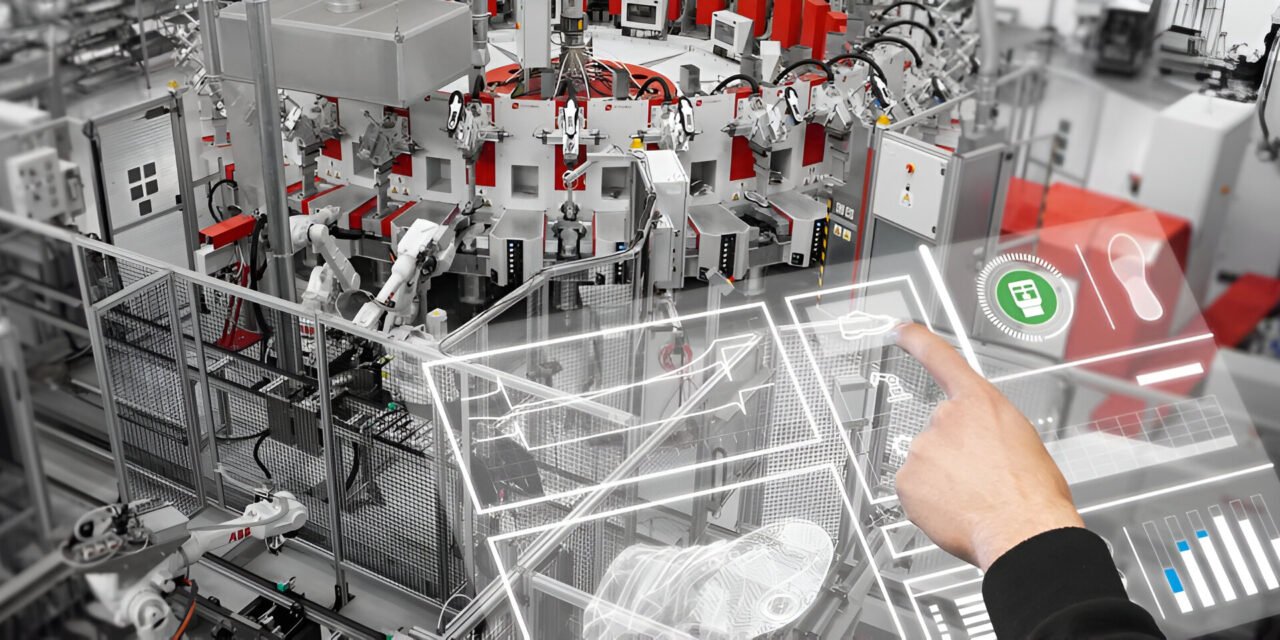

The footwear industry is rapidly embracing automation technologies to enhance production efficiency, improve precision, and reduce costs. Here are the latest automation technologies being implemented in footwear factories:

1. Robotic Assembly Systems

- Automated Cutting, Stitching, and Lasting:

- Robots equipped with precision tools handle tasks such as cutting leather, stitching uppers, and lasting (shaping the upper around the shoe last).

- Increases speed and consistency compared to manual processes.

- Advantages:

- Improves accuracy and reduces defects.

- Handles repetitive and labor-intensive tasks, freeing workers for higher-level activities.

2. 3D Printing

- Applications:

- Rapid prototyping for testing new designs.

- Manufacturing complex components like lattice-structured midsoles.

- Customization of insoles and uppers tailored to individual foot shapes.

- Advantages:

- Reduces waste by using additive manufacturing techniques.

- Speeds up development cycles and enables on-demand production.

3. Laser Cutting and Engraving

- Applications:

- Precise cutting of leather and synthetic materials for uppers and components.

- Engraving decorative patterns, logos, or monograms.

- Advantages:

- Enhances precision and reduces material wastage.

- Allows intricate and unique designs that were previously difficult to achieve.

4. Vision-Based Quality Control Systems

- How It Works:

- Cameras and sensors inspect each component and finished product for defects such as irregular stitching, uneven cuts, or surface imperfections.

- Advantages:

- Improves quality assurance by detecting flaws earlier in the process.

- Reduces human error in visual inspections.

5. Automated Material Handling

- Applications:

- Conveyor belts, robotic arms, and automated guided vehicles (AGVs) transport materials and components within the factory.

- Advantages:

- Streamlines workflows and reduces manual handling.

- Increases safety and efficiency in the factory environment.

6. Computerized Cutting Machines

- Applications:

- CNC (Computer Numerical Control) machines cut leather and fabric components with high precision.

- Advantages:

- Reduces material waste by optimizing pattern layouts.

- Ensures consistent quality in mass production.

7. Smart Sewing Machines

- Features:

- Equipped with sensors and programmable controls for automated stitching.

- Capable of complex stitch patterns and decorative work.

- Advantages:

- Reduces manual intervention, ensuring uniform stitching quality.

- Speeds up production and allows for intricate designs.

8. Digital Lasting Machines

- How It Works:

- Automates the process of shaping the shoe upper around the last.

- Uses robotic arms or pneumatic systems for precise and consistent results.

- Advantages:

- Enhances efficiency and reduces labor-intensive processes.

- Ensures a uniform fit and shape across all shoes.

9. Advanced Adhesive Application Systems

- Features:

- Automated systems apply adhesives with precision, reducing waste and improving bond strength.

- Robots or spray systems ensure even application on soles and uppers.

- Advantages:

- Reduces manual errors and ensures consistent adhesion.

- Minimizes exposure of workers to fumes.

10. Artificial Intelligence (AI) and Machine Learning

- Applications:

- Predictive maintenance for machinery to minimize downtime.

- Optimizing production schedules based on demand forecasts.

- Enhancing quality control by identifying defects through AI-driven image recognition.

- Advantages:

- Improves operational efficiency and reduces costs.

- Enables smarter, data-driven decision-making.

11. Internet of Things (IoT)

- Applications:

- Sensors embedded in machinery monitor performance and provide real-time data.

- IoT-enabled systems connect all stages of production, ensuring seamless communication.

- Advantages:

- Enables predictive maintenance and real-time monitoring.

- Improves traceability and transparency in the manufacturing process.

12. Flexible Manufacturing Systems (FMS)

- How It Works:

- Modular automation systems allow factories to switch between different styles or models of shoes with minimal downtime.

- Advantages:

- Accommodates small-batch or custom production.

- Enhances factory flexibility to meet changing market demands.

13. Sustainable Manufacturing Technologies

- Applications:

- Automation in recycling materials and reducing waste.

- Use of waterless dyeing and automated eco-friendly processes.

- Advantages:

- Reduces environmental impact and aligns with sustainability goals.

- Attracts eco-conscious consumers.

14. Digital Twins

- How It Works:

- Virtual models of production lines simulate and optimize factory operations.

- Advantages:

- Identifies bottlenecks and optimizes workflows before implementing changes.

- Reduces downtime and improves productivity.

15. Direct Injection Molding

- Applications:

- Automated systems inject materials directly into molds to create soles or integrate components like midsoles and outsoles in one step.

- Advantages:

- Enhances precision and consistency.

- Reduces the need for adhesives or additional assembly steps.

Benefits of Automation in Footwear Factories

- Efficiency: Faster production cycles with reduced lead times.

- Consistency: Uniform quality across large production batches.

- Cost Reduction: Optimized resource use and reduced labor costs.

- Customization: Enables bespoke and small-batch production without significant cost increases.

- Sustainability: Minimizes waste and energy consumption.

Automation technologies are reshaping footwear manufacturing, making it more efficient, precise, and adaptable to market trends while meeting consumer demands for high-quality and sustainable products.

Hashtags

#FootwearAutomation #SmartShoeFactories #AutomatedFootwearProduction #InnovationInShoemaking #TechInFootwearManufacturing #ShoeFactoryAutomation #AdvancedFootwearTech #FutureOfShoemaking #AutomatedLeatherCrafting #SmartManufacturingFootwear