Processed leather finishes are achieved through a variety of techniques and treatments applied during the final stages of leather production. These finishes determine the appearance, texture, durability, and intended use of the leather. Depending on the final product (e.g., bags, shoes, furniture, or apparel), tanneries use specific finishing methods to enhance leather’s performance and aesthetic appeal.

Here’s a breakdown of how different leather finishes are achieved for various uses:

1. Aniline Finish

- Process:

- Leather is dyed using transparent aniline dyes without applying any surface coating or pigments.

- The natural grain, pores, and imperfections of the leather remain visible.

- Characteristics:

- Soft, smooth, and luxurious with a natural look.

- Develops a rich patina over time.

- Highly breathable.

- Common Uses:

- High-end bags, briefcases, furniture, and fashion accessories.

- Pros: Natural appearance, excellent feel, and aging properties.

- Cons: Susceptible to staining, fading, and scratches. Requires careful maintenance.

2. Semi-Aniline Finish

- Process:

- Leather is dyed with aniline dyes and then coated with a light pigment layer for uniform color and protection.

- Characteristics:

- Retains much of the natural grain while offering improved stain resistance and durability.

- Slightly more uniform in appearance than pure aniline leather.

- Common Uses:

- Premium handbags, automotive upholstery, and furniture.

- Pros: Balance of natural appearance and durability.

- Cons: Still requires some care to maintain the finish.

3. Pigmented Finish

- Process:

- Leather is coated with opaque pigments to cover imperfections and create a consistent color.

- Additional layers of polymer coatings are applied for protection.

- Characteristics:

- Uniform color and appearance with high durability.

- Resistant to stains, fading, and wear.

- Common Uses:

- Car upholstery, furniture, briefcases, and everyday bags.

- Pros: Highly durable, easy to clean, and affordable.

- Cons: Less natural-looking and may feel less soft than aniline finishes.

4. Nubuck Finish

- Process:

- Top-grain leather is sanded or buffed on the grain side to create a velvety texture.

- Characteristics:

- Soft, luxurious feel with a matte appearance.

- Slightly more durable than suede since it comes from top-grain leather.

- Common Uses:

- High-end bags, shoes, and upholstery.

- Pros: Elegant and soft to the touch.

- Cons: Prone to staining and water damage; requires maintenance.

5. Suede Finish

- Process:

- The underside of split leather (lower hide layers) is buffed to create a fuzzy, napped texture.

- Characteristics:

- Soft, lightweight, and flexible.

- Matte appearance with a unique texture.

- Common Uses:

- Footwear, jackets, gloves, and accessories.

- Pros: Affordable, soft, and visually appealing.

- Cons: Less durable than full-grain leather and prone to stains and moisture damage.

6. Patent Finish

- Process:

- Leather is coated with multiple layers of polyurethane (PU) or lacquer to achieve a high-gloss, mirror-like finish.

- Characteristics:

- Shiny, reflective surface with a polished appearance.

- Water-resistant but less breathable.

- Common Uses:

- Fashion bags, dress shoes, belts, and accessories.

- Pros: Eye-catching and waterproof.

- Cons: Prone to scuffing and cracking with excessive use.

7. Embossed Finish

- Process:

- A heated metal plate with a specific pattern or texture (e.g., crocodile, snakeskin, or geometric designs) is pressed onto the leather surface.

- Characteristics:

- Adds decorative patterns or textures while hiding surface imperfections.

- Common Uses:

- Luxury bags, wallets, belts, and automotive interiors.

- Pros: Aesthetic variety and uniform surface.

- Cons: Requires careful maintenance to preserve the embossed texture.

8. Antiqued or Distressed Finish

- Process:

- Leather is treated with dyes, oils, and sometimes mechanical processes (e.g., buffing or tumbling) to create a worn, vintage look.

- Characteristics:

- Aged, rugged appearance with uneven tones.

- Often feels soft and supple.

- Common Uses:

- Vintage-style bags, jackets, and boots.

- Pros: Unique, character-rich look; durable.

- Cons: May show wear more easily.

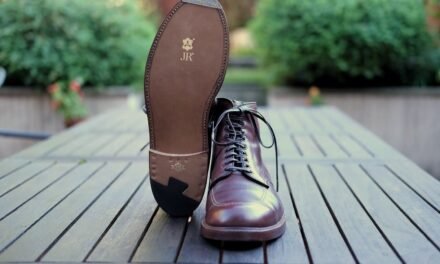

9. Pull-Up Finish

- Process:

- Leather is infused with oils or waxes during tanning. When stretched or bent, the waxes move, creating a lighter tone in those areas.

- Characteristics:

- Distinctive, rugged appearance with color variations.

- Develops a rich patina over time.

- Common Uses:

- Briefcases, bags, furniture, and boots.

- Pros: Durable, beautiful patina with age.

- Cons: Requires occasional conditioning to maintain the finish.

10. Metallic Finish

- Process:

- Leather is coated with a thin layer of metallic foil or pigments to create a shiny, reflective surface.

- Characteristics:

- Bold, eye-catching finish with metallic tones (e.g., silver, gold, or bronze).

- Common Uses:

- Fashion bags, shoes, and accessories.

- Pros: Unique and stylish appearance.

- Cons: The metallic layer may wear off over time.

11. Water-Resistant and Waterproof Finishes

- Process:

- Leather is treated with wax coatings, silicone sprays, or polymer layers to improve its water resistance.

- Characteristics:

- Protects the leather from moisture without compromising flexibility.

- Common Uses:

- Outdoor gear, travel bags, and footwear.

- Pros: Protects against rain and spills.

- Cons: May reduce breathability.

Conclusion

Different leather finishes are achieved through dyeing, coating, embossing, and chemical treatments, each tailored to the leather’s end-use. High-end leather bags and portfolios often favor aniline, semi-aniline, or pull-up finishes for a natural and luxurious look, while more practical applications (like furniture or car upholstery) use pigmented and water-resistant finishes for durability. The choice of finish depends on functionality, aesthetic preferences, and market demands.

Hashtags

#LeatherDesign #HandcraftedLeather #LeatherArtistry #LeatherIndustry #LeatherTrends #LeatherAccessories #LeatherLifestyle #LeatherGoods #LeatherStyle #LeatherFashion #LeatherFurniture #LeatherTechnology #LeatherCare #LeatherMaintenance #LeatherInnovation #LeatherProducts #LeatherExperts #LeatherExperts #LeatherExperts #LeatherExperts #LeatherExperts