Tanneries are increasingly adopting wastewater treatment and recycling practices to address environmental concerns and meet regulatory standards. Here’s how tanneries are incorporating sustainable practices:

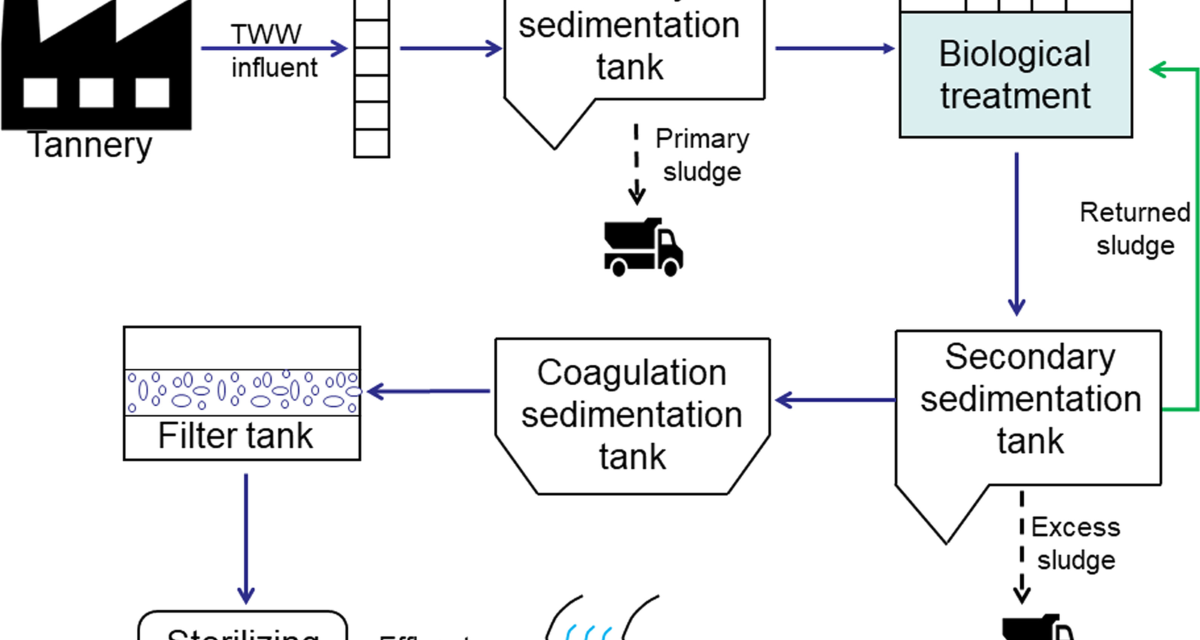

1. Effluent Treatment Plants (ETPs)

- Description: Tanneries set up Effluent Treatment Plants to treat wastewater before it is released into the environment.

- Processes:

- Physical Treatment: Screening, sedimentation, and filtration to remove large solids.

- Chemical Treatment: Addition of coagulants to remove dissolved contaminants.

- Biological Treatment: Using microorganisms to break down organic matter in the wastewater.

2. Closed-Loop Water Recycling Systems

- Description: Tanneries implement closed-loop water systems to recycle water and reduce consumption.

- Process:

- Water is used multiple times in the tanning process before being treated and reused.

- Helps conserve freshwater and reduces dependency on external water sources.

- Benefits: Reduces water usage by up to 70-80% in some systems.

3. Zero Liquid Discharge (ZLD) Systems

- Description: ZLD systems aim to ensure that no wastewater is discharged into the environment.

- Process:

- All water is treated and reused within the tannery.

- Any residual sludge is treated and converted into solid waste or reused in other processes.

- Benefits: Reduces pollution, prevents contamination, and improves sustainability.

4. Use of Biological Agents

- Description: Enzyme-based treatments and biological agents are being used to reduce toxic chemicals in wastewater.

- Process:

- Enzyme treatments help break down complex compounds in the water, making it easier to treat.

- Helps reduce the need for harsh chemicals that can harm the environment.

- Benefits: Minimizes chemical use and leads to safer effluent.

5. Reverse Osmosis (RO) Filtration

- Description: Reverse Osmosis is used to purify and treat wastewater.

- Process:

- Water is passed through semi-permeable membranes that remove impurities and salts.

- The filtered water can be reused in the tannery.

- Benefits: Effective in treating both organic and inorganic pollutants and producing high-quality recycled water.

6. Sludge Management and Disposal

- Description: Tanneries focus on effective management of sludge produced during wastewater treatment.

- Process:

- Sludge dewatering techniques (such as centrifuges) are used to reduce the volume of sludge.

- Sludge can be converted into biogas, fertilizers, or bricks for construction purposes.

- Benefits: Minimizes waste sent to landfills and contributes to a circular economy.

7. Adoption of Green Chemistry

- Description: Tanneries are exploring green chemistry techniques that reduce harmful chemicals in the tanning process.

- Process:

- Use of vegetable-based tannins instead of synthetic chemicals.

- Shift to chrome-free tanning methods, such as mineral-based tanning or bio-tanning.

- Benefits: Reduces the environmental footprint of both the wastewater and the leather itself.

8. Energy Recovery from Wastewater

- Description: Some tanneries are recovering energy from wastewater treatment processes.

- Process:

- Biogas generated from sludge treatment is used to power the tannery’s operations.

- Heat recovery systems can be used to reduce energy consumption in the treatment process.

- Benefits: Reduces energy costs and makes the tannery more energy-efficient.

9. Sustainable Chemical Management

- Description: Tanneries are focusing on reducing the toxicity of chemicals used in the tanning process.

- Process:

- Adopting safer chemicals and minimizing the use of hazardous substances like chromium.

- Implementing systems for monitoring and controlling chemical waste in effluents.

- Benefits: Reduces contamination in wastewater and promotes sustainable manufacturing practices.

10. Compliance with Environmental Standards

- Description: Many tanneries are aligning their wastewater treatment processes with global environmental standards (e.g., ISO 14001, Leather Working Group (LWG)).

- Process:

- Regular audits and monitoring to ensure compliance with local and international regulations.

- Implementing best practices for water and waste management.

- Benefits: Ensures legal compliance and helps improve the tannery’s reputation in the market.

Conclusion

Tanneries are adopting advanced wastewater treatment technologies, closed-loop recycling, and sustainable practices to reduce their environmental impact. These innovations not only help conserve water and reduce pollution but also make the tanning process more economically efficient and environmentally responsible.

Hashtags

#SustainableFashion #EthicalLeather #EcoLeather #EcoChic #EcoFriendlyFashion #EcoFashion #EcoLeatherGoods #EcoLeatherAccessories #EcoLeatherBags #EcoLeatherShoes #EcoLeatherJackets #EcoLeatherBelts #EcoLeatherWallets #EcoLeatherPurses #EcoLeatherProducts #EcoLeatherCraftsmanship #EcoLeatherDesign #EcoLeatherStyle #EcoLeatherTrends #EcoLeatherMovement