Technology is significantly shaping the future of footwear production in various ways, leading to more efficient, sustainable, and innovative processes. Here are some key ways technology is influencing the footwear industry:

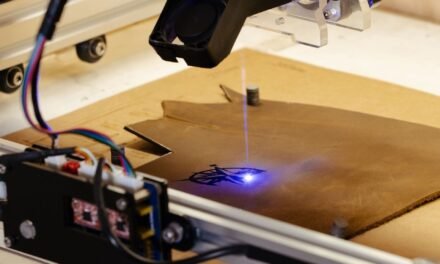

1. 3D Printing (Additive Manufacturing):

- Custom Design: 3D printing allows for highly personalized footwear, enabling brands to create shoes tailored to an individual’s foot shape and specific needs, improving comfort and performance.

- Prototyping and Speed: Designers can quickly prototype shoe models, reducing time to market and production costs. 3D printing also facilitates rapid testing of new materials and designs.

2. Smart Manufacturing and Automation:

- Efficiency: Automation and robotics are streamlining production lines, reducing labor costs and human error while increasing speed and precision in tasks like stitching, assembly, and cutting.

- Advanced Materials Handling: Automated systems can also handle complex materials, ensuring that every piece of footwear is produced with consistent quality.

3. Sustainability Innovations:

- Eco-friendly Materials: Technology is enabling the use of sustainable, plant-based, or recycled materials in footwear production. Examples include mushroom leather, pineapple fibers (Piñatex), and recycled plastics.

- Waterless and Chemical-free Tanning: New tanning processes that do not rely on harmful chemicals or excessive water consumption are being developed, significantly reducing the environmental impact of leather production.

4. Wearable Technology Integration:

- Smart Footwear: Shoes with embedded sensors are becoming more common. These sensors can track activity, monitor posture, and even provide real-time feedback on the wearer’s movement. For example, smart shoes can help runners improve their performance by analyzing their stride or provide medical benefits, such as aiding people with mobility issues.

- Health and Comfort Features: Technologies like pressure mapping, heat molding, and advanced cushioning systems are being used to improve comfort and performance, with shoes that adapt to foot movements and conditions.

5. Artificial Intelligence (AI) and Data Analytics:

- Design and Trend Forecasting: AI and machine learning algorithms analyze customer data to predict trends, optimize designs, and determine what styles, sizes, and colors will sell best, enabling brands to make more informed decisions.

- Inventory and Supply Chain Optimization: AI is being used to streamline inventory management, reduce waste, and forecast demand, leading to more efficient supply chains and reduced production costs.

6. Virtual Reality (VR) and Augmented Reality (AR):

- Virtual Fitting Rooms: AR technology enables customers to virtually try on shoes before making a purchase, improving the shopping experience and reducing returns. Virtual fitting rooms can also help customers visualize shoes on their feet in real-time through their smartphones or in-store displays.

- Design Visualization: VR allows designers to visualize and test shoe designs in a virtual environment before production, saving time and resources during the design process.

7. Robotics in Shoe Construction:

- Precision and Craftsmanship: Robots are becoming skilled in tasks like cutting, stitching, and assembling shoes with incredible precision, which traditionally required handcrafting. This results in higher quality and consistency across large production runs.