The leather industry is increasingly implementing advancements in waste management and recycling facilities to minimize its environmental impact and promote sustainability. Here are some key developments:

- Wastewater Treatment:

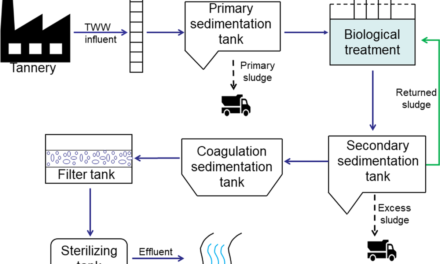

- Advanced Treatment Technologies: Tanneries are adopting advanced wastewater treatment technologies, such as membrane filtration, reverse osmosis, and biological treatment processes, to remove pollutants like chromium, sulfides, and organic matter before discharging effluent into water bodies.

- Closed-Loop Systems: Some tanneries are implementing closed-loop water systems, where wastewater is treated and reused within the production process, minimizing water consumption and reducing the discharge of pollutants.

- Solid Waste Management:

- Waste Minimization: Tanneries are focusing on waste minimization strategies, such as optimizing raw material usage, reducing trim waste, and implementing lean manufacturing practices.

- Recycling and Reuse: Leather waste, such as shavings, trimmings, and sludge, is increasingly being recycled and reused in various applications, such as:

- Production of leather meal: A protein-rich material used as animal feed.

- Production of biofertilizers and soil conditioners: Utilizing organic components of leather waste.

- Conversion into energy: Anaerobic digestion of organic waste to produce biogas for energy generation.

- Resource Recovery:

- Chromium Recovery: Technologies are being developed to recover chromium from tanning effluents, reducing the demand for new chromium and minimizing environmental impact.

- Water Recovery: Technologies like membrane filtration and reverse osmosis are used to recover water from wastewater, reducing water consumption and minimizing the discharge of pollutants.

- Technological Advancements:

- Cleaner Production Technologies: The adoption of cleaner production technologies, such as water-efficient tanning processes and the use of environmentally friendly chemicals, is reducing the generation of waste and minimizing environmental impact.

These advancements in waste management and recycling facilities are crucial for the sustainable development of the leather industry. By minimizing waste, reducing pollution, and promoting resource recovery, the industry can mitigate its environmental impact and contribute to a more sustainable future.