The process of cutting and stitching leather for garment production involves precise techniques to ensure quality, durability, and aesthetics. Here’s a step-by-step overview:

1. Leather Selection and Preparation

- Step: High-quality hides or skins are selected based on thickness, flexibility, and smoothness.

- Preparation:

- Leather is softened using conditioning methods.

- Imperfections like scars are identified to minimize waste during cutting.

2. Pattern Making

- Step: Patterns for garments (jackets, trousers, coats) are created using paper or digital software (CAD systems).

- Key Consideration: Patterns are laid to optimize leather use and avoid damaged areas.

3. Leather Cutting

- Manual Cutting:

- Skilled workers use sharp knives or scalpels for precise cuts, ensuring accuracy along the pattern edges.

- This method is used for small-scale or custom production.

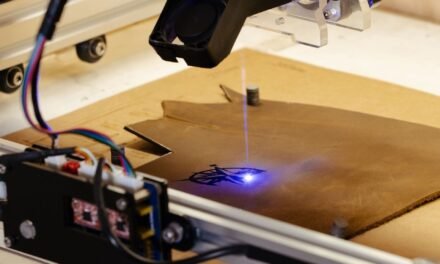

- Machine Cutting:

- For large-scale production, die-cutting machines or laser cutters ensure speed and uniformity.

- Challenges: Leather has no stretch (unlike fabric), so precision is critical to avoid errors.

4. Skiving (Edge Thinning)

- Step: Edges of leather pieces are thinned down to reduce bulk at seams and enhance flexibility.

- Tools Used:

- Skiving machines or manual tools like blades.

5. Stitching Leather Pieces

- Step: Leather pieces are stitched together using heavy-duty sewing machines designed for thick materials.

- Techniques Used:

- Lock Stitch: Common for durable seams.

- Top Stitching: Decorative and functional stitching along seams for reinforcement.

- Thread:

- Nylon, polyester, or waxed threads are used for strength.

- Thicker threads ensure the seams withstand stress.

- Needles: Special leather needles with wedge-shaped tips prevent tearing.

6. Seam Finishing

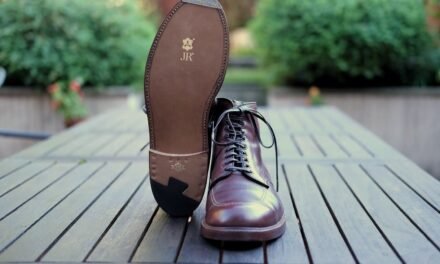

- Step: Seams are pressed flat and sometimes reinforced with leather glues or topstitching for durability.

- Optional: Edges may be treated with finishes (e.g., burnishing or edge paint) for a smooth, polished look.

7. Final Assembly and Detailing

- Step: Additional details like zippers, buttons, linings, and trims are added.

- Attention to Detail:

- Precise alignment of seams and components ensures a professional finish.

8. Quality Control

- Step: The finished garment undergoes inspection for:

- Stitch strength and alignment.

- Smooth seams and polished edges.

- Proper fitting and finishing.