Manufacturing leather bags involves a combination of traditional craftsmanship and modern techniques to produce durable, stylish, and functional products. The process typically includes design, material selection, cutting, stitching, assembly, and finishing. Here’s a step-by-step overview of how leather bags are made:

1. Design and Planning

- Concept and Sketch:

- Designers create initial sketches or digital renderings of the bag, including dimensions, features, and aesthetic details.

- Pattern Creation:

- Patterns for each part of the bag (e.g., panels, pockets, straps) are made using cardboard or software like CAD. These patterns serve as templates during production.

2. Material Selection

- Leather Type:

- Full-grain, top-grain, or corrected-grain leather is selected based on the bag’s purpose and desired quality.

- Exotic leathers (e.g., crocodile, ostrich) or eco-friendly options (e.g., synthetic or bio-leathers) may be used for specific designs.

- Lining Materials:

- Fabrics like canvas, suede, or polyester are chosen for the interior lining.

- Accessories and Hardware:

- Zippers, buckles, rivets, and straps are sourced to complement the design and functionality.

3. Leather Preparation

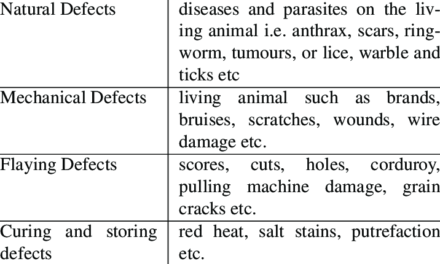

- Inspection:

- The leather is inspected for defects like scars or uneven textures.

- Conditioning:

- Leather may be treated with conditioners to soften it and make it easier to work with.

- Cutting:

- Using patterns, the leather is cut into the required shapes and sizes using:

- Hand tools (knives, scissors) for bespoke bags.

- Die-cutting machines for mass production, ensuring precision and consistency.

- Using patterns, the leather is cut into the required shapes and sizes using:

- Edge Skiving:

- Edges of leather pieces are thinned (skived) to reduce bulk and ensure smooth seams.

4. Stitching and Assembly

- Marking:

- Stitching lines and alignment points are marked on the leather pieces to ensure accuracy during assembly.

- Sewing:

- Pieces are sewn together using industrial sewing machines or by hand for intricate designs.

- Saddle stitching, a durable hand-sewing technique, is often used for high-end leather bags.

- Reinforcements:

- Stress points like handles and corners are reinforced with additional stitching or rivets.

- Lining Attachment:

- The interior lining is sewn or glued into place, depending on the design.

5. Hardware Installation

- Attachment:

- Metal hardware such as buckles, zippers, and D-rings are installed using rivet presses or hand tools.

- Finishing Touches:

- Handles, straps, and decorative elements are added and securely fastened.

6. Edge Finishing

- Edge Burnishing:

- Raw edges are smoothed using sanding tools, then sealed with edge paint or wax for a polished look.

- Dyeing:

- The edges may be dyed to match or contrast with the bag’s main color.

7. Quality Control

- Inspection:

- Each bag is inspected for defects, including uneven stitching, loose threads, or alignment issues.

- Testing:

- Stress tests are conducted on handles, zippers, and seams to ensure durability.

- Cleaning:

- The bag is cleaned and polished to remove any residue from the production process.

8. Branding

- Logos and Personalization:

- Logos, monograms, or custom designs are embossed, debossed, or printed on the bag.

- Labeling:

- Tags or labels indicating the brand, material, and care instructions are attached.

9. Finishing and Packaging

- Final Touches:

- The bag is given a final inspection, polished, and conditioned for a premium appearance.

- Packaging:

- High-quality bags are placed in dust bags or protective covers and packaged in branded boxes for shipping or retail display.

10. Distribution

- Retail and Online Sales:

- Finished leather bags are distributed to stores, showrooms, or e-commerce platforms for sale.

- Custom Orders:

- For bespoke bags, personalized orders are delivered directly to customers.

Techniques and Tools

- Traditional Craftsmanship:

- Hand-stitching, embossing, and manual cutting are used for bespoke or luxury leather bags.

- Modern Manufacturing:

- Automated cutting and sewing machines are employed for mass production, ensuring efficiency and uniformity.

- Laser Cutting and Engraving:

- Advanced tools provide precise cutting and allow for intricate patterns or logos.

Sustainability Trends in Leather Bag Manufacturing

- Eco-Friendly Materials:

- Use of plant-based or recycled leathers, such as cactus leather or mushroom leather.

- Waterless Tanning:

- Adoption of tanning processes that minimize water usage and chemical waste.

- Waste Reduction:

- Utilizing leather offcuts for smaller accessories or patchwork designs.

Conclusion

The manufacturing of leather bags combines artistry and technology, from selecting premium materials to crafting designs that balance aesthetics and functionality. High-quality leather bags require skilled craftsmanship and attention to detail, ensuring their durability and timeless appeal.

Hashtags

#LeatherBagManufacturing #HandcraftedLeatherBags #LuxuryLeatherGoods #LeatherCraftsmanship #TimelessBagDesigns #LeatherProductionProcess #StylishLeatherAccessories #LeatherBagMaking #PremiumLeatherBags #ArtisanLeatherCrafts