Treating leather to make it water-resistant involves applying specific treatments and finishes to reduce the material’s natural porosity while maintaining its flexibility and durability. Here’s a detailed explanation of the techniques and products used to achieve water resistance in leather:

1. Wax or Oil Treatments

Wax and oil treatments are among the most traditional methods to waterproof leather.

Steps:

- Clean the Leather:

- Remove dirt and dust with a damp cloth or brush to ensure proper adhesion.

- Apply Wax or Oil:

- Use a high-quality leather wax (e.g., beeswax) or oil (e.g., mink oil, neatsfoot oil).

- Rub the product into the leather using a soft cloth or sponge in circular motions.

- Allow Absorption:

- Let the product soak into the leather for several hours.

- Buff the Surface:

- Buff the treated leather with a clean cloth to restore shine and remove excess product.

Benefits:

- Creates a protective barrier on the leather surface.

- Maintains flexibility and enhances the leather’s lifespan.

Drawbacks:

- May darken the leather color.

- Requires regular reapplication for continued effectiveness.

2. Waterproofing Sprays

Waterproofing sprays are convenient and effective for creating a water-resistant barrier on leather.

Steps:

- Clean the Leather:

- Ensure the leather is dry and free from debris.

- Apply the Spray:

- Hold the spray bottle 6–8 inches away and apply an even coat.

- Allow to Dry:

- Let the leather air dry for 24 hours in a well-ventilated area.

- Reapply as Needed:

- For optimal protection, apply multiple coats and reapply every few months.

Benefits:

- Easy to use and suitable for all leather types.

- Provides a transparent, non-sticky protective layer.

Drawbacks:

- Less durable than wax or oil treatments.

- Requires frequent reapplication, especially in wet conditions.

3. Silicone-Based Treatments

Silicone-based products are commonly used for heavy-duty waterproofing, especially for outdoor leather gear.

Steps:

- Clean the Leather:

- Remove dirt and ensure the leather is dry.

- Apply Silicone:

- Rub or spray the silicone product onto the leather evenly.

- Buff and Dry:

- Allow the silicone to dry, then buff for a polished finish.

Benefits:

- Highly effective for long-term water resistance.

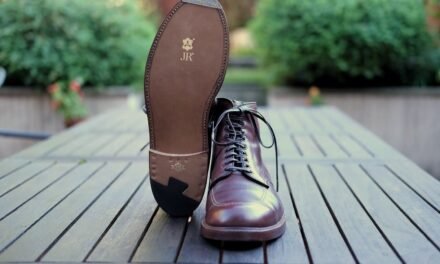

- Ideal for outdoor and rugged leather items, like boots or saddles.

Drawbacks:

- Can affect the breathability of the leather.

- May alter the leather’s texture or finish.

4. Polymer Coatings

Polymer-based treatments, like polyurethane, create a durable, water-resistant surface on leather.

Steps:

- Prepare the Leather:

- Clean and condition the leather to prevent cracking.

- Apply the Coating:

- Use a brush or sponge to apply a thin layer of polymer coating.

- Cure the Leather:

- Allow the coating to cure for several hours.

Benefits:

- Long-lasting and highly resistant to water and stains.

- Suitable for heavy-duty and industrial leather applications.

Drawbacks:

- Reduces the natural feel and breathability of the leather.

- Not ideal for fashion or soft leather items.

5. Fatliquoring During Tanning

During the tanning process, leather can be treated with oils and fats to improve its water resistance.

Process:

- Fatliquoring involves adding a mixture of oils, fats, and waxes to the leather during the tanning process.

- This method is integrated into the leather’s fibers, providing inherent water resistance.

Benefits:

- Produces leather with long-lasting water resistance.

- Commonly used for outdoor leather, such as saddles and boots.

Drawbacks:

- Increases production costs.

- Typically limited to specific leather types.

6. Synthetic Waterproof Coatings

Synthetic coatings provide a high level of water resistance and durability.

Types:

- Polyurethane (PU) Coating:

- Often used on synthetic or bonded leather.

- Acrylic Coatings:

- Adds a protective layer while maintaining the leather’s appearance.

Benefits:

- Excellent for industrial and commercial leather products.

- Long-lasting and highly protective.

Drawbacks:

- May reduce the leather’s natural look and feel.

- Less eco-friendly due to synthetic materials.

7. Water-Resistant Leather Types

Some leather types are inherently more water-resistant due to their tanning and finishing processes.

Examples:

- Chrome-Tanned Leather:

- Contains chromium salts that enhance water resistance.

- Waxed or Oiled Leather:

- Treated during tanning with oils or wax for built-in water resistance.

- Patent Leather:

- Coated with a glossy, impermeable finish for high water resistance.

Benefits:

- Requires less maintenance than untreated leather.

- Durable and ready for outdoor use.

Drawbacks:

- Limited to specific applications and styles.

8. Combination Treatments

For maximum water resistance, leather can undergo a combination of the above methods.

Process:

- Start with a tanning process that incorporates water-resistant chemicals.

- Add a surface treatment, like wax, spray, or silicone, for enhanced protection.

Applications:

- Ideal for high-performance leather goods, such as hiking boots, saddles, and automotive interiors.

Care and Maintenance for Water-Resistant Leather

- Regular Cleaning:

- Remove dirt and debris promptly to prevent damage.

- Conditioning:

- Apply leather conditioner periodically to maintain softness and prevent cracking.

- Reapply Treatments:

- Depending on the method used, reapply waterproofing products every 3–6 months.

- Avoid Overexposure:

- Prolonged exposure to water can eventually compromise water resistance, even in treated leather.

Conclusion

Treating leather for water resistance involves applying products like wax, oils, sprays, or polymer coatings, or using advanced tanning methods to create inherently water-resistant leather. The choice of treatment depends on the leather type, intended use, and desired appearance. Regular maintenance ensures the leather remains protected and functional over time.

Hashtags

#WaterResistantLeather #LeatherWaterproofing #ProtectiveLeatherTreatment #WaterproofLeatherGoods #SustainableLeatherCare #LeatherProtectionTechniques #WeatherproofLeather #LuxuryLeatherCare #WaterproofingSolutions #LeatherDurabilityEnhancement