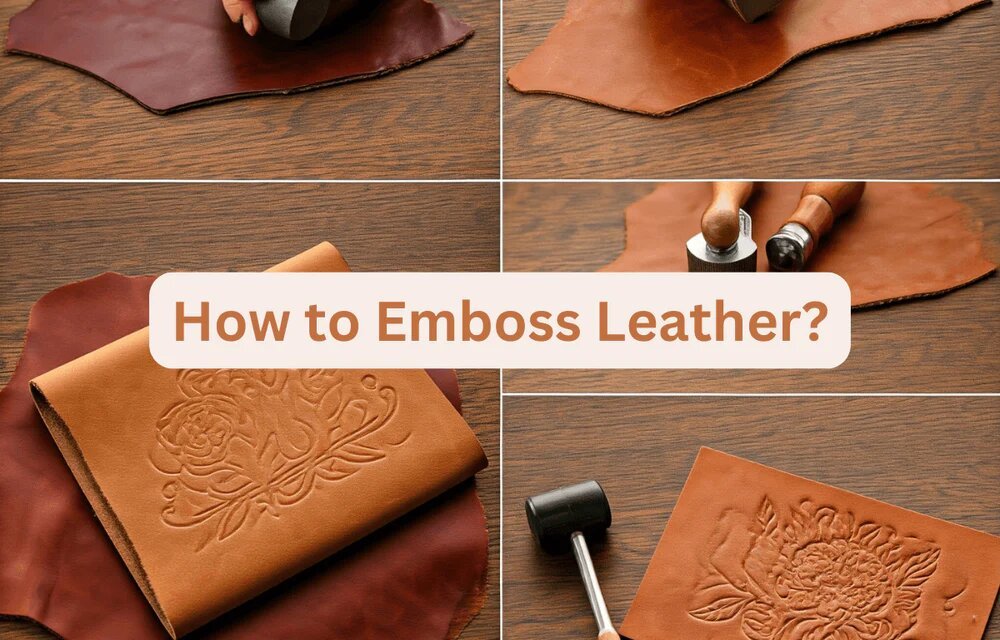

Embossing patterns on leather is a popular technique to add texture, design, or branding. It involves pressing or stamping designs into the leather surface using heat, pressure, or tools. Here are the key techniques for embossing patterns on leather:

1. Heat Embossing

Heat embossing uses heated tools or stamps to press patterns into the leather surface.

Steps:

- Prepare the Leather:

- Clean the leather surface and lightly dampen it to make it more pliable.

- Heat the Tool:

- Use a branding iron, metal stamp, or embossing plate and heat it to the desired temperature.

- Press the Tool:

- Apply firm, even pressure to the leather with the heated tool to imprint the pattern.

- Cool Down:

- Allow the leather to cool and set the design.

Applications:

- Logos, monograms, and intricate patterns.

- Common in fashion accessories and corporate branding.

2. Cold Embossing

Cold embossing uses a press or stamp without heat to imprint patterns on leather.

Steps:

- Prepare the Leather:

- Moisten the leather to make it soft and receptive to imprinting.

- Place the Stamp:

- Position the embossing plate or stamp on the leather.

- Press with Force:

- Use a hydraulic or manual press to apply consistent pressure.

- Release and Inspect:

- Remove the plate and check the embossed design.

Applications:

- Large-scale production where heat isn’t required.

- Used for creating subtle textures and patterns.

3. Hand-Tooling

Hand-tooling involves manually creating patterns on leather using specialized tools.

Steps:

- Dampen the Leather:

- Lightly wet the leather to make it soft for carving.

- Transfer the Design:

- Draw or trace the design onto the leather using tracing film.

- Tool the Design:

- Use tools like swivel knives, bevelers, and stamping tools to carve and emboss the pattern.

- Burnish the Surface:

- Polish or dye the embossed areas for added contrast.

Applications:

- Custom or intricate designs in artisan leatherwork.

- Often used for belts, wallets, and book covers.

4. Debossing

Debossing presses the pattern below the leather surface, creating a sunken effect.

Steps:

- Prepare the Leather:

- Clean and condition the leather.

- Use a Metal Stamp:

- A custom die or metal plate with the desired pattern is positioned on the leather.

- Apply Pressure:

- Use a heat press or manual press to imprint the design.

- Optional Foil:

- Add metallic or colored foil between the stamp and leather for a decorative effect.

Applications:

- Luxury branding, such as logos on bags, wallets, and labels.

5. Foil Embossing

Foil embossing combines embossing with colored or metallic foil for decorative effects.

Steps:

- Place the Foil:

- Position a sheet of foil (gold, silver, or colored) on the leather.

- Apply the Stamp:

- Use a heated stamp or plate to press the foil into the leather, transferring the design.

- Peel Off Excess Foil:

- Remove unused foil to reveal the embossed pattern.

Applications:

- Decorative designs on luxury leather goods, including handbags and journals.

6. Laser Engraving

Laser engraving creates embossed or carved patterns using precision lasers.

Steps:

- Prepare the Design:

- Create or upload a digital design to the laser machine.

- Position the Leather:

- Place the leather under the laser head.

- Engrave the Pattern:

- The laser cuts or burns the surface to create the desired texture or depth.

- Finish:

- Clean the surface to remove any residue from the engraving.

Applications:

- Intricate designs, logos, and personalization for leather accessories.

7. Rolling Embossing

Rolling embossing uses rollers with engraved patterns to imprint designs continuously on leather.

Steps:

- Load the Leather:

- Feed the leather into a rolling embossing machine.

- Adjust the Rollers:

- Set the pressure and speed of the rollers.

- Emboss the Pattern:

- The rollers press the design onto the leather as it passes through.

- Inspect and Cut:

- Inspect the embossed leather and cut it to size.

Applications:

- Large-scale production of patterned leather for upholstery, shoes, and bags.

8. Blind Embossing

Blind embossing uses no ink or foil, creating a subtle, raised effect on leather.

Steps:

- Prepare the Leather:

- Clean and dampen the leather surface.

- Use a Die:

- Position a metal die with the desired pattern on the leather.

- Press or Stamp:

- Apply heat and pressure to imprint the design.

- Finish:

- Optionally, condition or polish the embossed leather.

Applications:

- Discreet branding and minimalist designs.

9. 3D Embossing

3D embossing creates raised, multi-dimensional patterns for added texture and depth.

Steps:

- Create a Mold:

- Use a custom 3D die or mold with the desired pattern.

- Heat and Press:

- Heat the leather and press it into the mold using high pressure.

- Cool and Release:

- Let the leather cool to hold the raised design.

Applications:

- Decorative applications in luxury goods and custom projects.

10. Stamping with Hydraulic Press

Hydraulic presses provide consistent pressure for large-scale, precise embossing.

Steps:

- Set the Die:

- Position the custom metal die on the leather.

- Apply Pressure:

- Use the hydraulic press to evenly stamp the pattern.

- Inspect the Result:

- Ensure the embossing is uniform and adjust if needed.

Applications:

- Industrial embossing for high-volume production.

Key Considerations in Embossing

- Leather Type:

- Full-grain and top-grain leather are best for embossing due to their smooth, durable surfaces.

- Tools and Equipment:

- High-quality stamps, dies, and presses ensure precision and durability.

- Design Complexity:

- Hand-tooling is ideal for intricate designs, while rolling or laser methods suit large-scale patterns.

- Finishing:

- Dyes, edge painting, or burnishing enhance the embossed designs.

Conclusion

Embossing techniques for leather range from traditional hand-tooling to advanced laser engraving and industrial rolling. The choice of method depends on the design complexity, scale of production, and desired aesthetic, making embossing a versatile technique for creating unique and durable leather accessories.

Hashtags

#LeatherEmbossingTechniques #EmbossedLeatherDesigns #LeatherCraftingMethods #ArtisticLeatherPatterns #LuxuryLeatherCraft #EmbossingInLeatherGoods #DecorativeLeatherCraft #EmbossedLeatherAccessories #LeatherDesignInnovation #LeatherPatternCreation